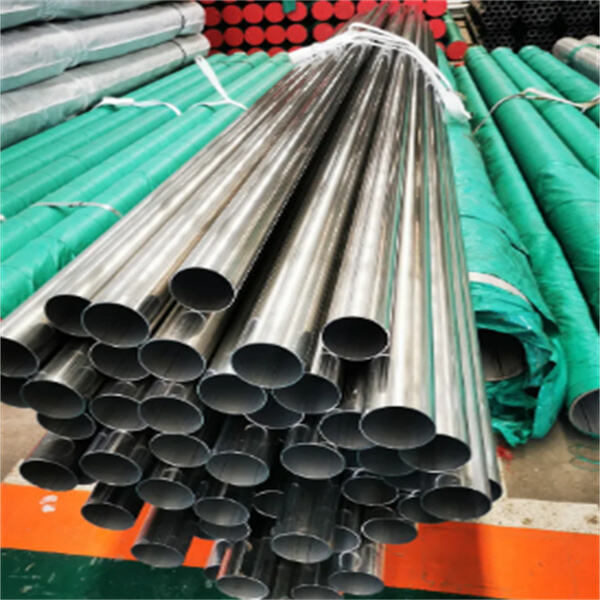

كم مرة توقفت لتفكر في كيفية تثبيت الأنابيب المعدنية معًا؟ يعمل اللحام عن طريق إذابة قطعتين من المعدن ثم ربطهما معًا باستخدام الحرارة (وأحيانًا يتم وضع مادة حشوة) أثناء عملية خاصة. مثلما نلصق صفحين من الورق باستخدام الغراء، وهذا يشبه نوع الترابط الذي يتم على المعدن باستخدام الحرارة. لحام أنابيب الستانلس ستيل: عندما يتعلق الأمر بلحام جميع أنابيب الستانلس ستيل (والتي تُعرف غالبًا باسم SS)، فإننا نوصي باستخدام الأدوات والطرق المناسبة لضمان استمرار قوة أنبوبك وقدرته على الاستمرار لفترة أطول دون كسر/تسرب.

لحام الغاز الخامل باستخدام التنجستن (TIG)، والمعروفة أيضًا بلحام القوس الكهربائي بالتنجستن، هي طريقة مثالية لأنابيب الستانلس ستيل. تتضمن استخدام أداة خاصة تسمى الكاثود وهي مصنوعة من معدن التنجستن. من ناحية أخرى، ينقل التنجستن الحرارة بشكل جيد للغاية. بالإضافة إلى الكاثود، يوجد أيضًا غاز خامل (الأرجون في هذا الفيديو). هذا الغاز الخامل ضروري لأنه يعمل كدرع لحماية حوض اللحام من الهواء والمواد الأجنبية، مما سيتسبب في جعل اللحام هشًا. أنابيب ss تستخدم هذه العملية أيضًا مادة ملء لتوصيل قطع المعدن. يقوم التنجستن بتسخين المعدن، وفي نفس الوقت يوجد غاز خامل محيط للحفاظ على النظافة: لا شيء يدخل إلى اللحام سوى هذين العنصرين.

إعداد أنابيب الستانلس ستيل قبل البدء في اللحام. إذن الخطوة الأولى هي تنظيف الأنابيب بشكل جيد جدًا حتى تتمكن من إزالة كل شيء، وهذا يعني تنظيفها من الأوساخ والدهون أو أي شيء آخر على هذا النحو بشكل جيد للغاية. إنها مثل غسل اليدين قبل الأكل، تريد القيام بذلك بشكل جيد في البداية بحيث لن تضطر للتعامل مع الفوضى لاحقًا. بمجرد تنظيف الأنابيب، يجب التأكد من أن الأنابيب مُحاذَة ومُثبَّتة بحيث لا تتحرك أثناء اللحام.

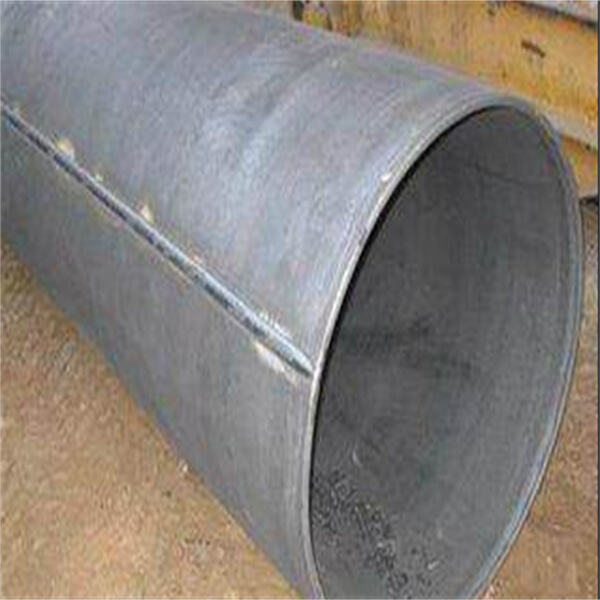

واحدة من الاستعدادات الأخرى هي اختيار نوع مناسب من رابطة اللحام. رابطة اللحام هي النقطة التي يتم فيها ربط قطعتين معدنيتين معًا. الجينغzheng أنابيب من غير المقاوم للصدأ الرابطة التي تختارها ستعتمد على مدى سماكة أنبوب الستانلس ستيل وما يحتاجه. تصميم رابطة اللحام له تأثير كبير على مدى قوة اللحام الخاص بك، لذلك من الضروري جدًا اختيار المناسب.

يختلف أيضًا حسب طريقة لحام أنابيب الستانلس ستيل، حيث يجب استخدام المادة الملأية عند نوع اللحام الخاص بالستانلس ستيل. المادة الملأة هي ما يربط بين قطعتي المعدن وتلعب دورًا مهمًا في جعل اللحام قويًا. ال قطر أنبوب ss مواد الملء المستخدمة لأنابيب الستانلس ستيل تشمل الستانلس ستيل، سبائك النيكل والتitanium وغيرها. لكل منها مميزاته التي تناسب أفضل السيناريوهات المختلفة.

عند لحام أنابيب الستانلس ستيل، يتم استخدام مواد ملء شائعة مثل SS304 وغيرها بشكل متكرر. إنها قوية ومتينة ومقاومة للصدأ؛ وبالتالي لا توجد مشاكل فيما يتعلق بموثوقيتها. وبالمثل، المواد الأخرى مثل إينكونيل - سبائك النيكل - فهي أيضًا شائعة جدًا عند لحام أنابيب الستانلس ستيل، حيث تعمل القطع الملحومة بإينكونيل بشكل أفضل في السيناريوهات ذات درجات الحرارة العالية. التيتانيوم هو أيضًا نوع من المواد الملأة الذي يمكن استخدامه للحام أنابيب الستانلس ستيل، خاصة عندما تكون القوة العالية والوزن الخفيف من المتطلبات الرئيسية.

التشقق: هذا أنبوب فولاذي 304 قد يحدث مشكلة عندما يكون اللحام ساخناً جدًا أو إذا لم يكن المادة الحشوة متوافقة مع أنبوب الستانلس ستيل. قم بتعديل إعدادات الحرارة وتأكد من أن المادة الحشوة التي تستخدمها مناسبة لنوع أنبوب الستانلس ستيل.

توجد شركة شاندونغ تشانغشينغدا للصلب المحدودة في قاعدة أنابيب الصلب الأكبر التي تنتج أنابيب الصلب باللحام السلس والمجهزة بورش إنتاج قياسية. تم تأسيس الشركة في عام 2011 كـ "وحدة تنفيذ مشروع برنامج وطني 863". توظف الشركة أكثر من 800 عامل، منهم 120 فنيًا متوسط وعالي المستوى. يمتد المصنع على مساحة 200,000 متر مربع. إنه منشأة إنتاج دولية تجمع بين توفير المواد الخام، وإنتاج المنتج النهائي، والمبيعات.

شركة شاندونغ تشانغشينغدا للصلب المحدودة لديها أكثر من خبرة في استيراد وتصدير لحام أنابيب الصلب (SS)، ولديها نظام سلسلة توريد كامل في أكثر من 150 دولة حول العالم. سيتيح هذا للعملاء شراء المنتجات دون مغادرة منازلهم. وفي الوقت نفسه، فإن فهم شامل لأنظمة الجمارك والرسوم الجمركية في مختلف الدول سيساعد العملاء في تقديم الحل الأكثر كفاءة للواردات، مما يمكّنهم من الاستمتاع بأفضل خدمة جودة وبأقل تكلفة.

برنامج الضمان لما بعد البيع هو ميزة أخرى تميزنا عن لحام الأنابيب من نوع SS لمنافسينا. سيتولى فريقنا لما بعد البيع المسؤولية عن أي مشكلات تحدث، مثل مشكلات الجودة، أو مشكلات النقل أو تأخير التسليم، خلال فترة التأمين المغطاة. من الناحية الاقتصادية وخلال عملية التعاون المستقبلية، سنقدم لعملائنا تعويضًا محددًا وسنقدم أفضل الاستراتيجيات والحلول لأي مشكلات قد تنشأ أثناء عملية التعاون المستقبلي، مما يضمن عدم قلق العملاء عند إجراء المشتريات.

شركة لحام الأنابيب الفولاذية هي شركة تمتلك مجموعة واسعة من المرافق الإنتاجية، بما في ذلك الدرفلة الساخنة، الدرفلة الباردة، الطلاء، الجلفنة والتفتيش على الجودة. كما أنها معتمدة لنظام التحكم في الجودة 90001. إنتاجها السنوي الذي يتجاوز المليون طن من الفولاذ يسمح لها بالحفاظ على جودة عالية لمنتجاتها وكذلك الحفاظ على مخزون قدره 100000 طن متاحة دائمًا طوال العام. إنها شريك موثوق يمكنه بسهولة تلبية احتياجات العملاء العاجلة المتعلقة بالتسليم، الفحص الجيد، والمزيد من المتطلبات.