Steel gas pipe is a kind of pipeline which transports natural or other gases from one place to another. This is made up of metallic metal often known as stain steel pipe, containing a much longer lifespan and also extremely reliable. There are a lot of important details to know about steel gas pipe, such as how to insert it in place and how you will be able to maintain it for the years that come

As with all steel gas pipe installation, it is crucial to obey safety standards. This entails using proper safety equipment such as gloves and goggles, ensuring your pipe is well-fitted in order to optimize smoke flow for a better hit (we cover this more at the bottom of our article), and examining whether any gas leaks exist that could prove life-threatening. By taking these precautions, you avoid accidents and confirm that everything is working as it should

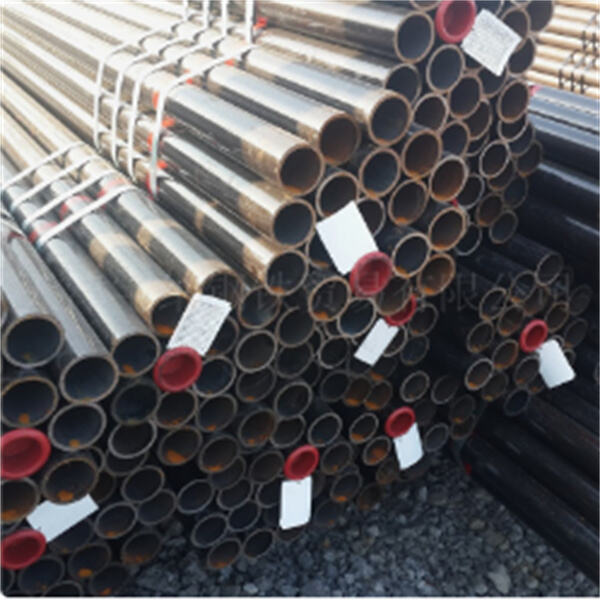

There are many pros and benefits for you to choose gas mild steel pipe while building your own home. One of the major features is that it possesses great strength and durability which extends beyond needlessly replacing them every now and then. It is also water and moisture resistant, which ensures it will not deteriorate due to rust. Unlike black iron pipe, steel gas line can be bent to fit into hard spaces around a property.

One of the best things about steel gas pipe is that it can often be less expensive than other types of natural gas pipe stainless. That makes it a great option for consumers saving on their electricity bills. Also steel is the more environmentally-friendly choice as unlike concrete it can be recycled. The selection of materials that can be recycled is one way to keep our mother earth a place for generations.

Steel Gas Pipe on the other hand, is very important to look after it if you want it to work as long backup source for your generator. This involves regularly inspecting the roof for signs of damage, washing the surface as required and repairing any leaks or issues that arise. Courtesy of We are Fun Regular maintenance keeps everything in order

If you put them on your steel gas pipe, take care to wash the surface with a soft brush and some soap in order not to allow it to become dirty. This can get rid of the dirt and grime that has been collecting for a few weeks in some speed cases. Rust can be another issue and it is important to check for this on a regular basis, as catching the problem early itself could mean saving yourself from facing any bigger problems.

Shandong Changshengda Steel Co., Ltd. offers the complete production lines including Steel gas pipe, cold rolling galvanizing, cold drawing painting, and quality inspection, and has successfully completed the 90001 quality control system certification. With an annual production of more than 1 million tonnes of steel, it is able to ensure the quality stability of the products and maintain the stock of over 100000 tons of goods on the spot all through the year. It is a reliable supplier who can satisfy the demands for urgent delivery, quality inspections, and other requirements of its customers.

Shandong Changshengda Steel Co., Ltd. It has over 12 years' experience in the field of export and import. It has a supply chain system that includes 150 countries, which Steel gas pipe customers to import items without leaving their home. At the same time, having a profound understanding of the customs and tariff structures across different countries can assist customers in providing the most efficient options for imports, which allows them to receive the best quality service at a low cost.

The guarantee program for after-sales is another benefit that distinguishes us from competitors Our after-sales division will take responsibility for any issues that might arise like quality problems transportation problems or delays in delivery within the period covered by insurance We will compensate customers on the economic level as well as when we collaborate in the future and provide the best solutions to Steel gas pipe any problems

Shandong Changshengda Steel Co., Ltd. is located in China's Steel gas pipe seamless steel pipe base. It is equipped with standard production workshops. The company was established in the year 2011 and is a "National 863 Program Project Implementation Unit". The company employs around 800 people including 120 senior and technical middle personnel. The facility is a multinational production facility with an area of 200000 square meters that combines the production of raw materials, production and sale.